LPZINC® <ZnO Filler for Heat Dissipating>

In recent years, there has been a greater demand

than ever before for electronic components to

withstand higher temperatures.

This is due to the increased use of power equipment

and faster data transmission speeds.

Zinc oxide exhibits excellent properties as an

inorganic filler in composite materials such as

heat dissipation sheets and greases.

1. Required performance

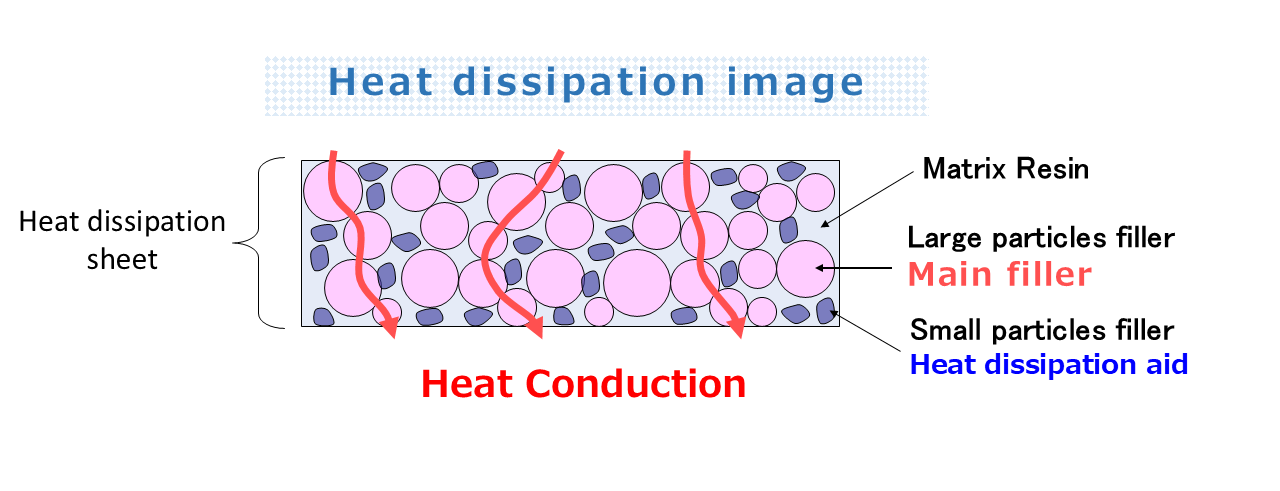

Heat dissipation materials consist of a matrix resin

and a heat dissipation filler.

The thermal conductivity of the matrix resin is

usually 0.1 to 0.3 W/mK, which is lower than

that of the heat dissipation filler, so the heat

dissipation performance mainly depends on the

heat dissipation filler.

In this case, small particle fillers alone do not

perform sufficiently due to increased thermal

resistance between filler particles and between

the particles and the resin.

Therefore, it is effective to use large particle fillers

as the main component to transfer heat more

effectively.

2. Comparison of various fillers

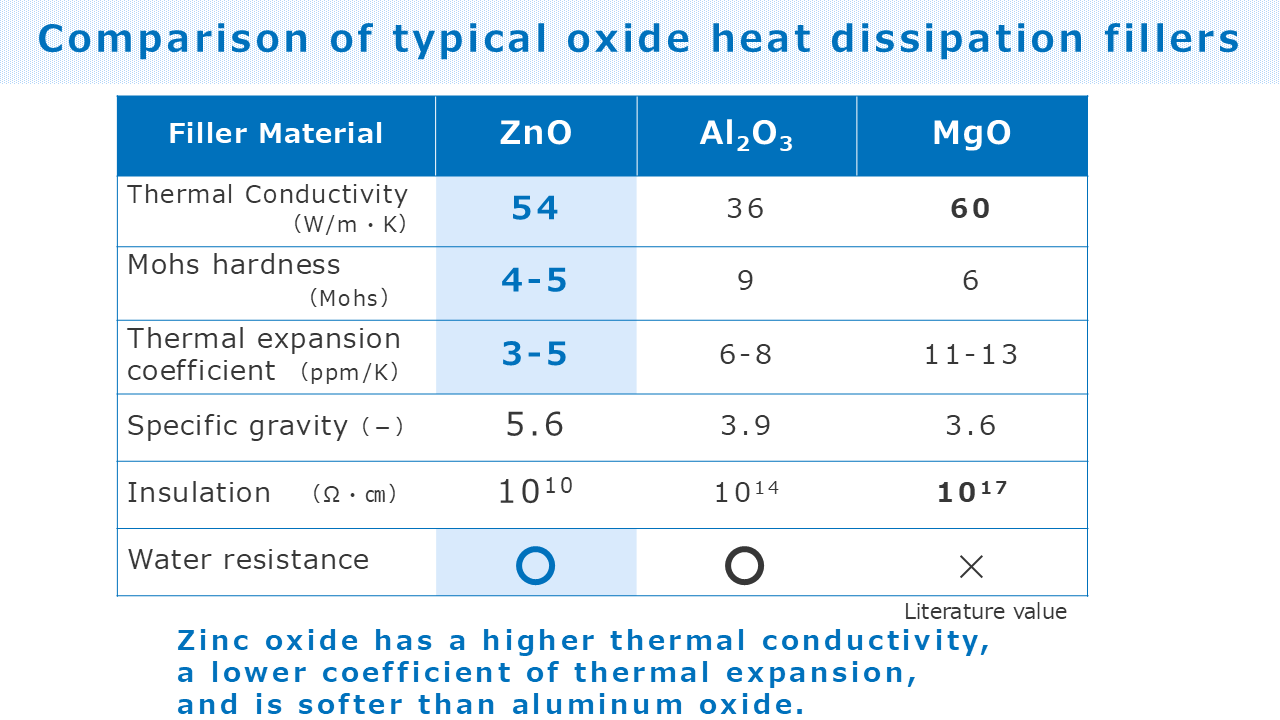

Compared to common oxide heat dissipation fillers

such as aluminum oxide and magnesium oxide,

zinc oxide has the advantage of high thermal

conductivity due to reduced contact thermal

resistance, and a low thermal expansion coefficient.

However, it should be noted that it has inferior

insulation properties.

In addition, zinc oxide has the advantage of

being a soft substance with a low Mohs hardness,

which significantly improves wear loss in kneading

and molding equipment.

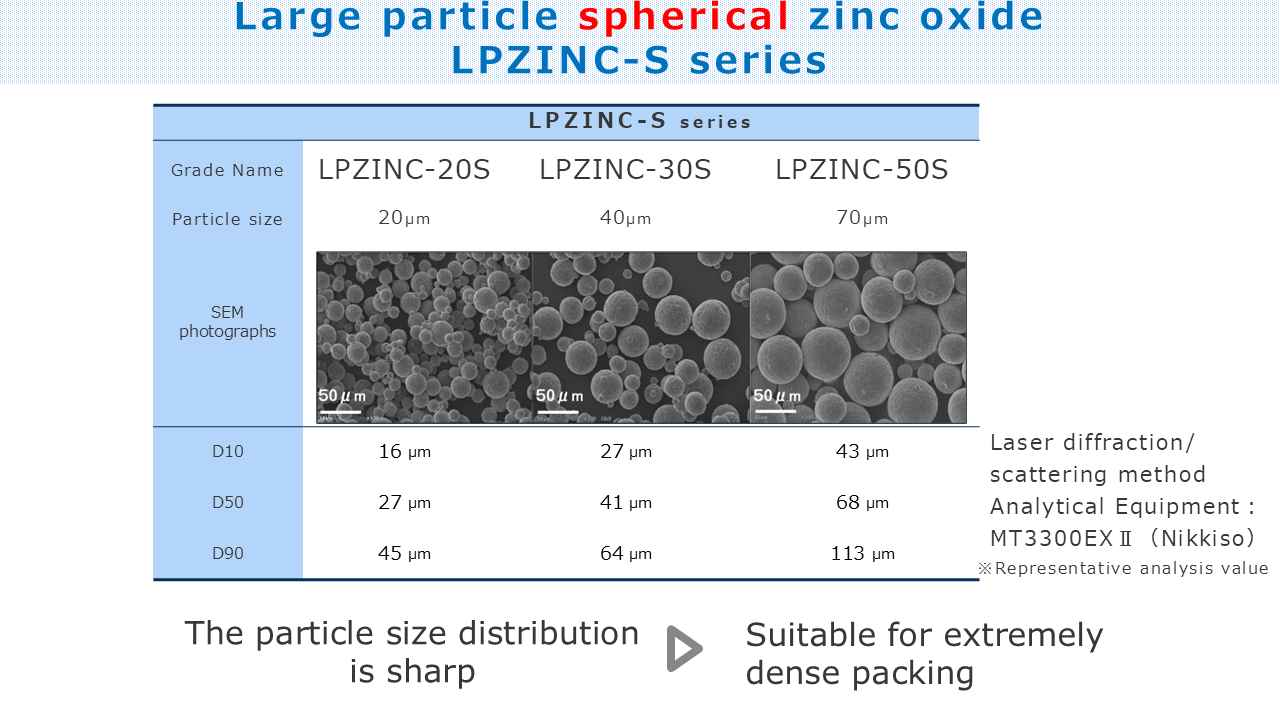

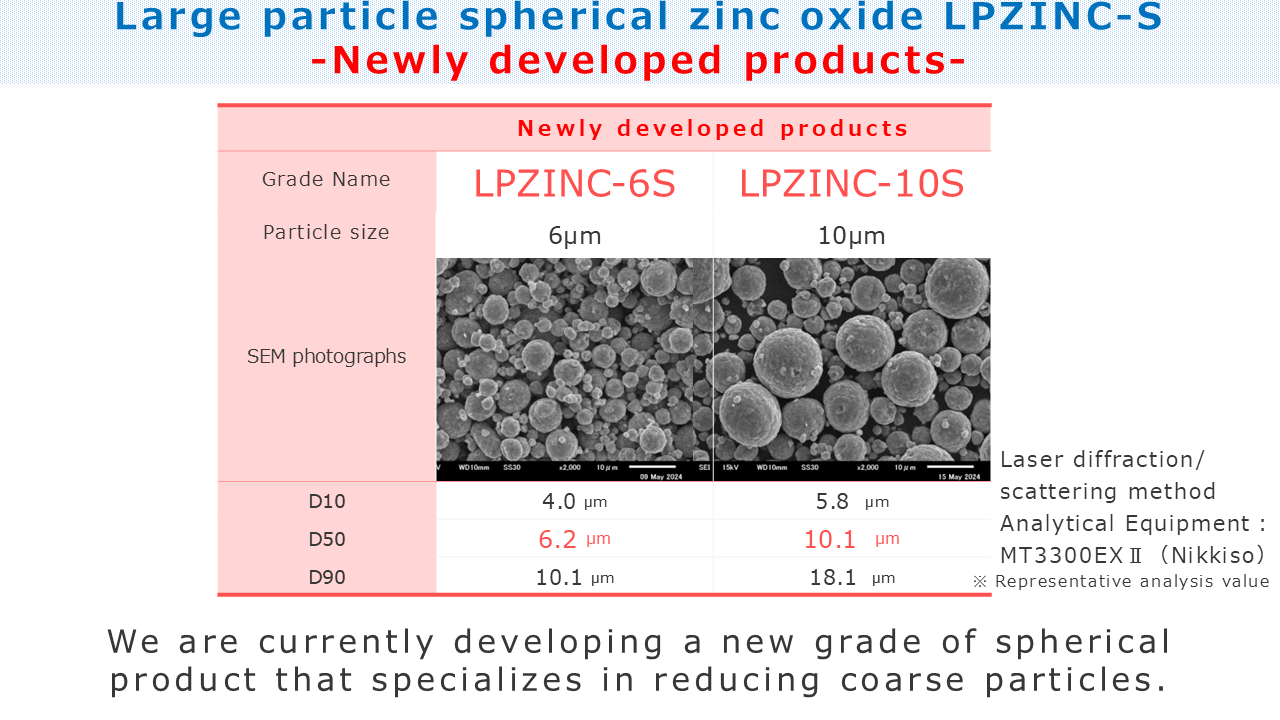

3. Introduction of large particle zinc oxide products

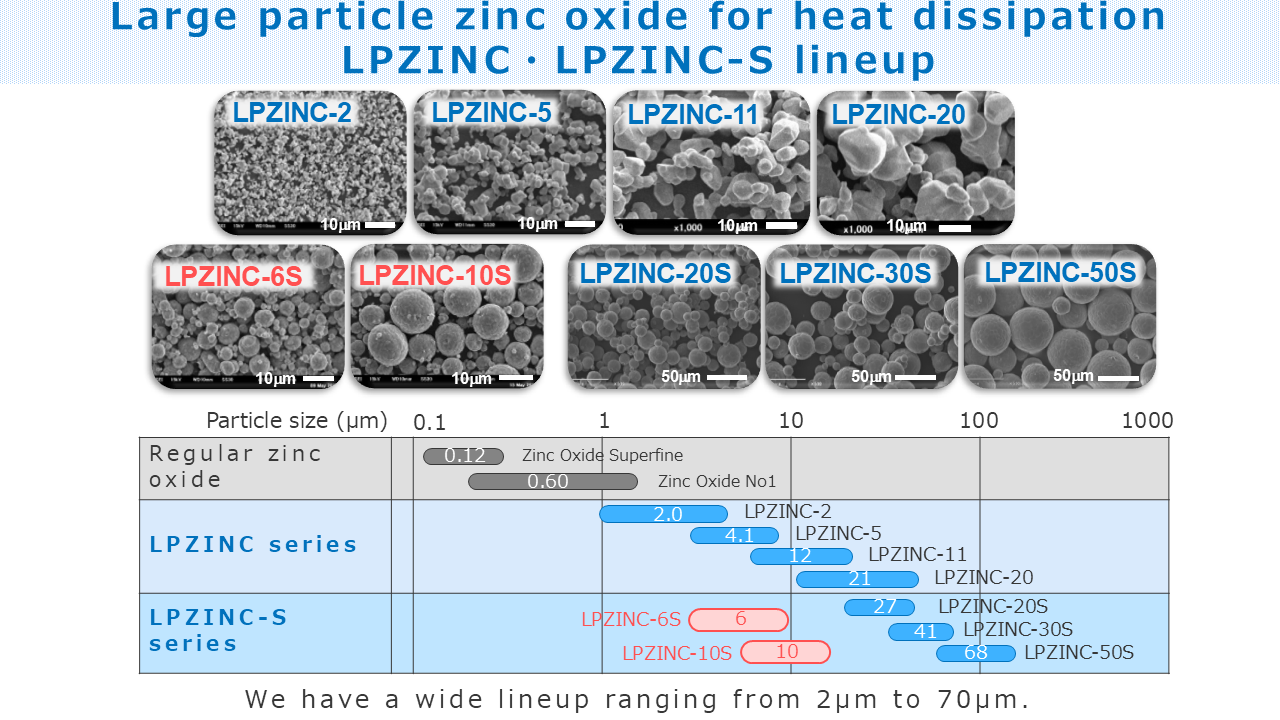

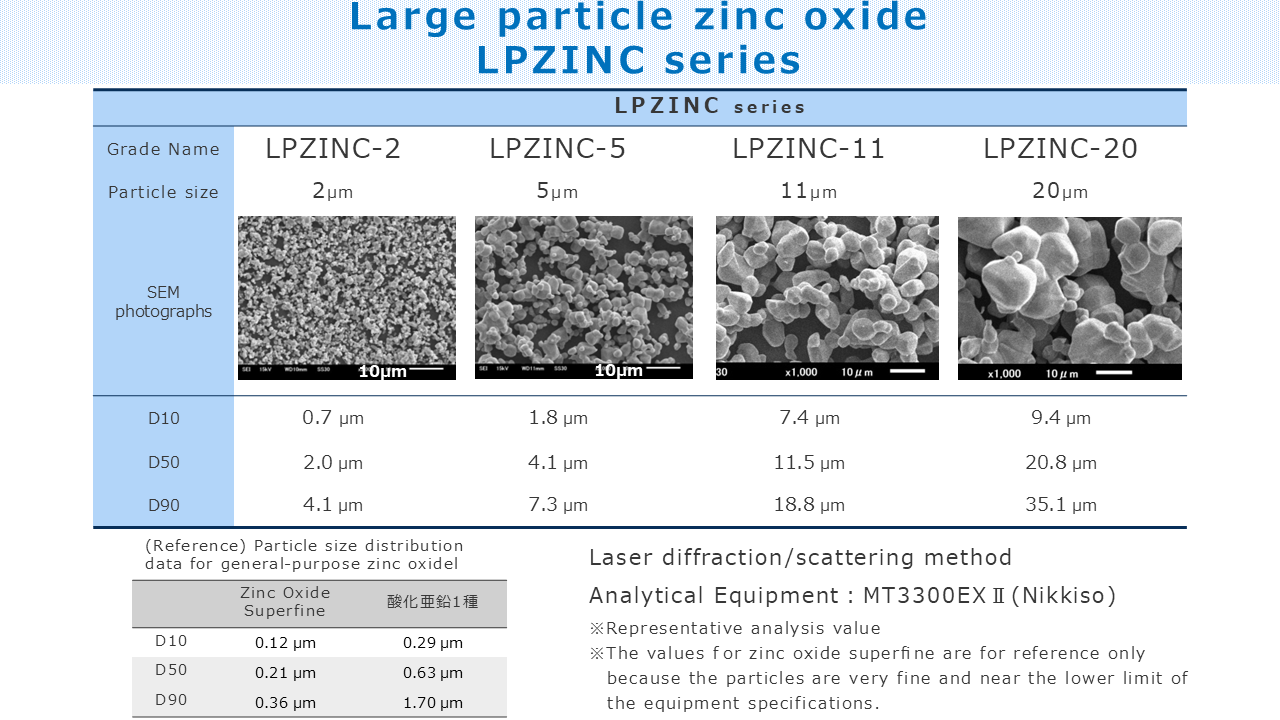

We have developed distinctive large-particle zinc

oxide products by controlling particle size and

shape using our outstanding technology.

We offer two types of products: irregular and

spherical.

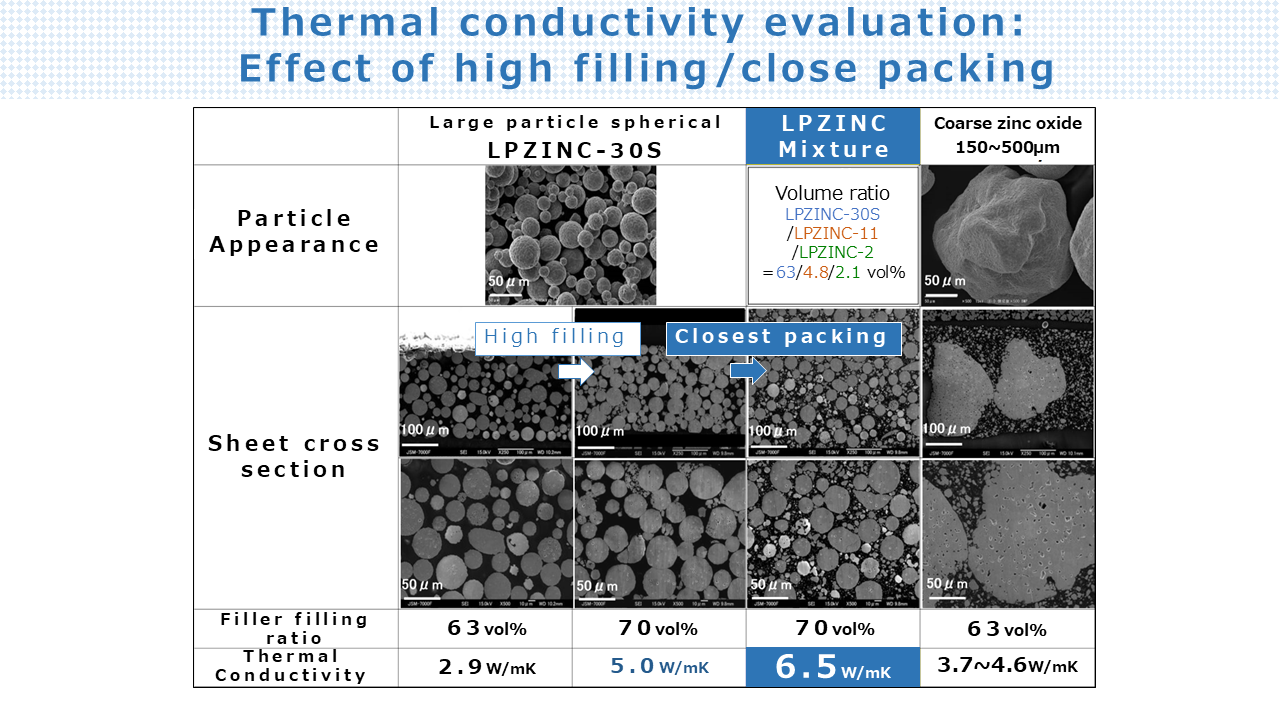

4. Effect of high filling/close packing

When the soft zinc oxide particles are densely

packed, they come into surface contact and

connect like beads.

This tendency is further intensified when large

and small particles are closely packed at a high

concentration.

As shown in the photo below, when the gaps

between large particles (LPZINC-30S) are filled

with small particles (LPZINC-2, 11) to achieve

close packing, the thermal conductivity is increased

even more than when only large particles are used

to increase the packing rate.

However, it is not necessarily true that the larger

the particle size of the main filler, the better.

With coarse particles whose particle size is not

properly controlled, the filler will be unevenly

distributed when mixed with the resin, and some

particles will crumble, causing variations in thermal

conductivity.

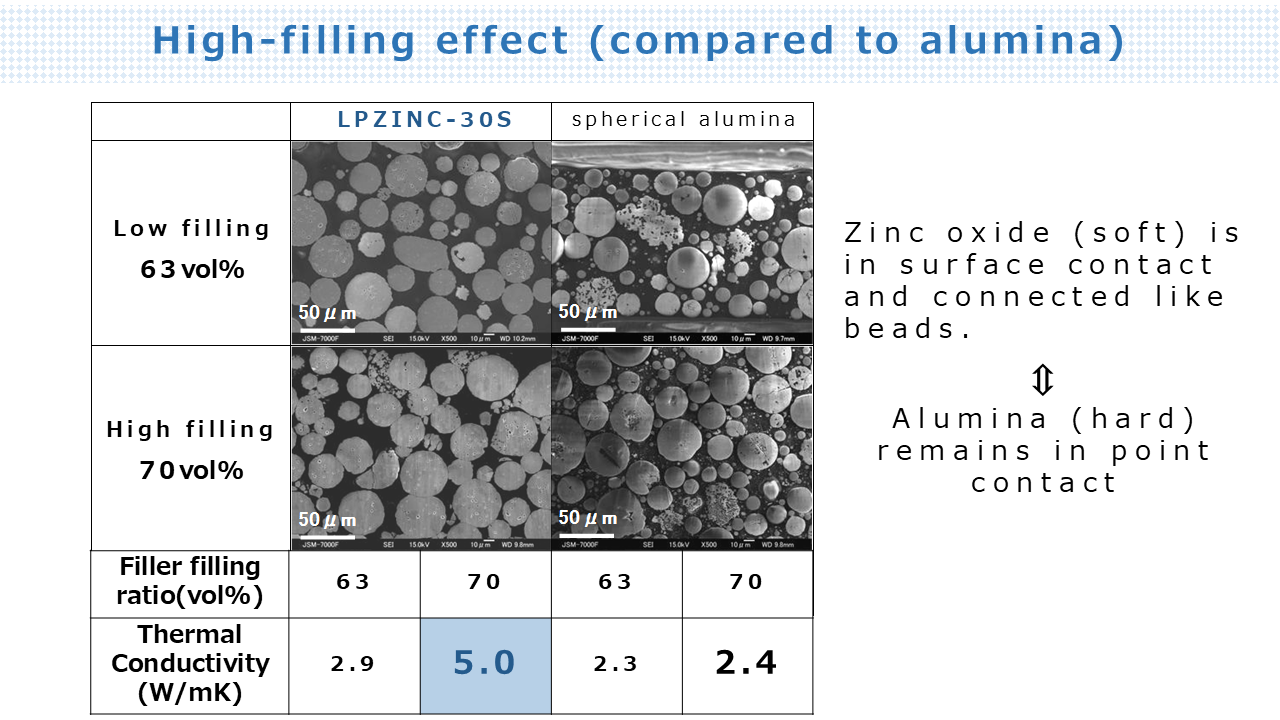

Another feature of zinc oxide is that it has a greater

high-filling effect than alumina.

While alumina, which has high hardness, tends

to remain in point contact, zinc oxide has more

surface contact, which expands the heat dissipation

path and is thought to increase thermal conductivity.

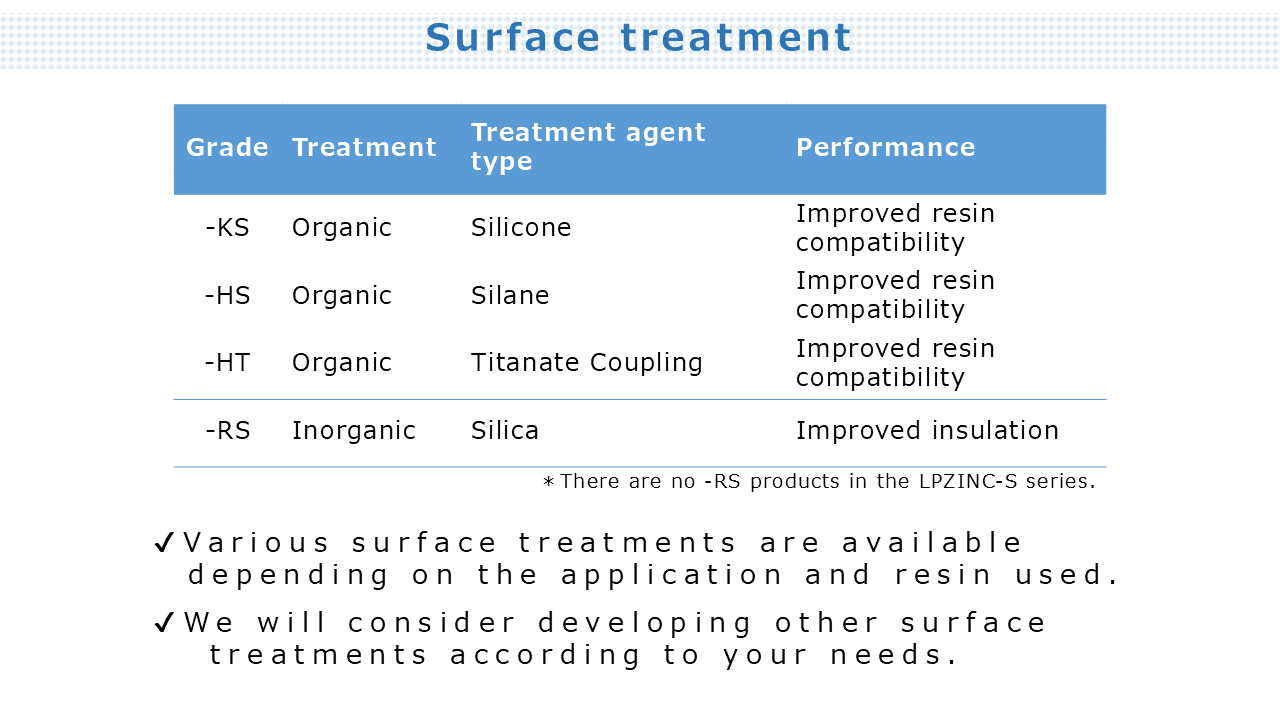

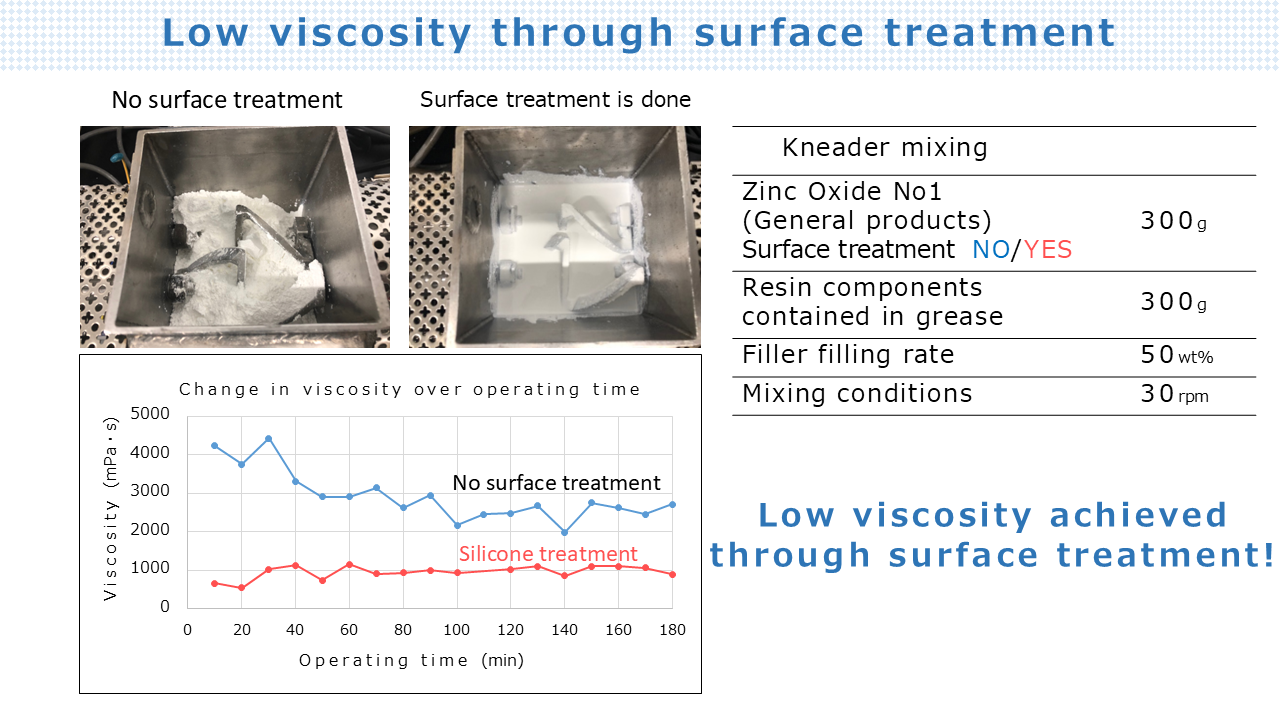

5. Effect of surface treatment

Surface treatment of inorganic powders is one of

Sakai Chemical’s core technologies.

Organic treatment improves resin affinity, resulting

in low viscosity during mixing.

Inorganic silica treatment is also expected to

improve insulation properties.

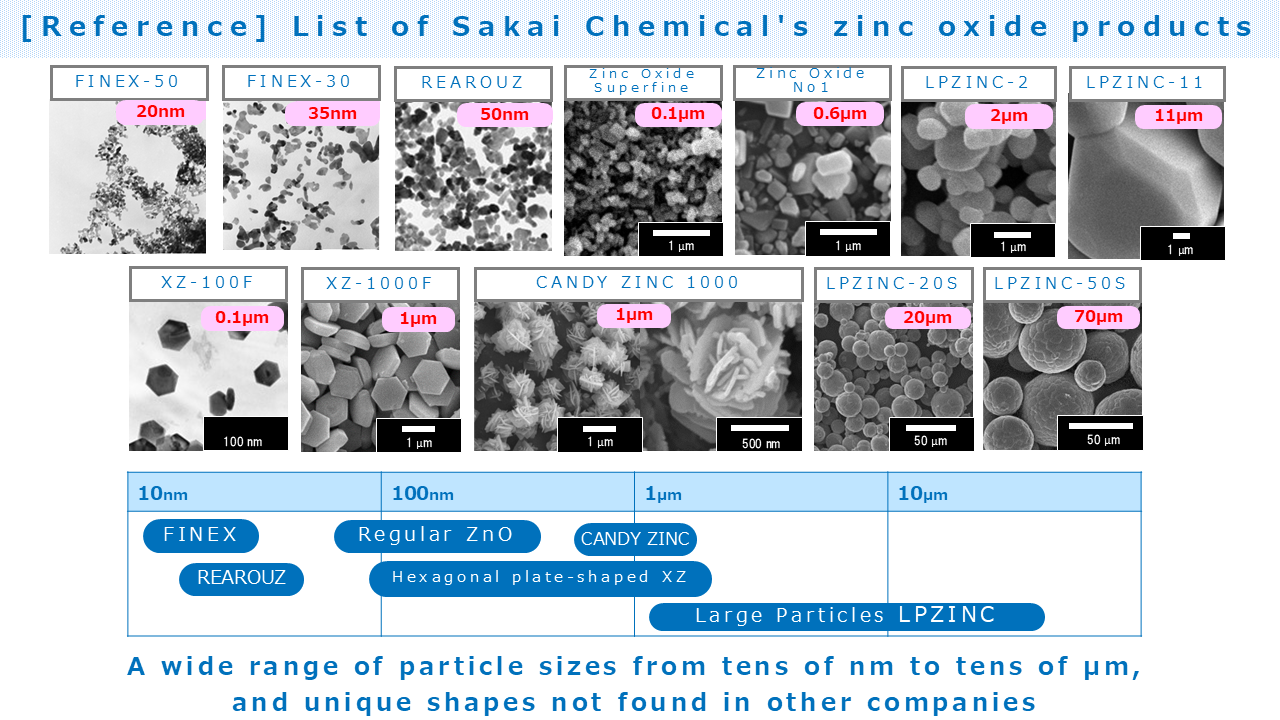

[Reference] List of Sakai Chemical's zinc oxide products

We offer a lineup of zinc oxide in a wide range of

particle sizes and unique shapes, such as hexagonal

plates and petal shapes.

If you would like to request a sample, please use

the inquiry form on this page.

We look forward to hearing from you.

お問い合わせ先

Inorganic Chemicals Sales Department

(TOKYO)

TEL:+81-3-5823-3722

(OSAKA)

TEL:+81-72-223-4155